Hydraulic Press Square Mold: Key Features and Applications

A hydraulic press square mold is a specialized tool used in conjunction with a hydraulic press to form, shape, or compress materials into square or rectangular shapes. The hydraulic press provides the necessary force, while the mold defines the shape and dimensions of the final product. These molds are commonly used in industries such as manufacturing, metalworking, ceramics, and composite materials, where precision and uniformity in shaping are critical.

In this article, we will explore the key features, materials, applications, and benefits of hydraulic press square molds.

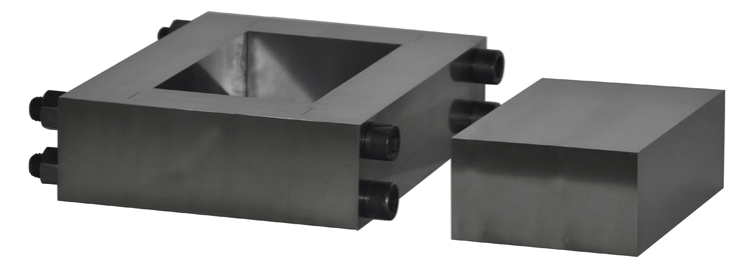

●What is a Hydraulic Press Square Mold?

A Square Hydraulic Press Die is a tool that consists of a die and a corresponding punch, which are used together to shape a material through the application of hydraulic pressure. The mold cavity is typically square or rectangular in shape, allowing for the production of parts or components with these geometries.

In a typical operation, the material is placed inside the mold cavity, and the hydraulic press applies pressure, forcing the material to conform to the shape of the mold. This process can be used for shaping metals, plastics, ceramics, rubber, and composite materials, depending on the specific mold design and press setup.

●Key Features of Hydraulic Press Square Molds

1.Material Composition

Hydraulic press square molds are usually made fromhigh-strength steel oralloyed materials to withstand the high forces generated by the hydraulic press. The material must be durable enough to resist wear, deformation, and cracking during repeated use.

2.Precision Engineering

Molds are precision-engineered to ensure uniformity and consistency in the final product. This includestight tolerances for dimensions, surface finishes, and angles, ensuring that each molded part meets exact specifications.

3.Customizability

Hydraulic press molds can be customized for specific applications, allowing for variations in size, depth, surface texture, and material handling. Custom molds are often designed based on the specific needs of the product being manufactured, whether it's a metal component or a plastic part.

4.Temperature Control

In some cases, molds may feature integratedheating or cooling elements to control the temperature of the mold during the pressing process. This is especially important for thermoplastic or composite materials that require specific temperatures to achieve optimal forming conditions.

5.Wear Resistance

Hydraulic press molds are typically treated withsurface coatings like nitriding or hard chrome plating to improve wear resistance and extend the life of the mold. This ensures the mold can handle high pressures and repeated use without degrading quickly.

6.Interchangeable Components

For flexibility and cost-effectiveness, molds can be designed withinterchangeable components such as inserts or plates. This allows manufacturers to modify the mold for different sizes or product shapes without needing to produce a completely new mold.

●Applications of Hydraulic Press Square Molds

Hydraulic press square molds are versatile and used in a wide range of industries and applications, including:

1.Metal Forming

Square molds are frequently used insheet metal forming processes, such asstamping anddeep drawing , to create metal parts with square or rectangular cross-sections. Applications include producing automotive components, structural parts, and metal casings for electronic devices.

2.Ceramics and Composites

In theceramics andcomposite materials industries, hydraulic press molds are used to shape raw materials into precise square forms for use in tiles, building materials, or specialized technical ceramics. Molds for these applications must handle high pressures while maintaining dimensional accuracy.

3.Plastic Molding

Forthermoplastic and thermoset materials, hydraulic press square molds are used to create parts such as containers, housings, and enclosures. These molds must be capable of handling the heating and cooling cycles required for plastic molding processes, such ascompression molding .

4.Rubber and Elastomer Products

Hydraulic press square molds are used in the production ofrubber orelastomer components , such as gaskets, seals, or shock absorbers. These molds need to accommodate the material's flexibility and elastic properties while ensuring consistent shapes.

5.Battery Manufacturing

In thebattery industry , hydraulic press molds are used to create battery components, includinganodes andcathodes for prismatic cells. The precision and uniformity provided by the mold ensure optimal cell performance and energy storage capabilities.

6.Powder Metallurgy

Square molds are used inpowder metallurgy , where powdered metals are compacted into square or rectangular shapes before being sintered to form solid components. These molds must be designed to apply even pressure across the entire material to ensure uniform density.

●Benefits of Hydraulic Press Square Molds

1.High Precision and Accuracy

Hydraulic press molds are engineered to offer precise shaping and forming, resulting in uniform parts with consistent dimensions and surface finishes. This level of accuracy is essential in industries such as aerospace, automotive, and electronics.

2.Versatility

Hydraulic press molds can be used with a wide variety of materials, including metals, plastics, ceramics, and rubber, making them versatile tools for manufacturing different types of products.

3.Efficiency in Mass Production

Using hydraulic presses with square molds allows for rapid production of large volumes of parts. The consistent, repeatable nature of the process makes it ideal for mass production applications.

4.Durability

Molds designed for hydraulic presses are built to withstand high pressures and temperatures, offering a long service life even under demanding production conditions. With proper maintenance, these molds can be used for thousands of cycles before requiring replacement.

5.Customizable Designs

Molds can be customized to meet specific product requirements, allowing manufacturers to create highly specialized parts or components with unique geometries.

●Conclusion

Ahydraulic press square mold is a key component in the manufacturing process for producing square or rectangular parts across a range of industries. With its high precision, durability, and versatility, this tool is essential for creating consistent and high-quality products from materials such as metals, plastics, ceramics, and rubber. As manufacturing demands grow, innovations in hydraulic press mold technology will continue to enhance production efficiency and expand the possibilities for custom part design.