Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with Laboratory equipments, technology, etc. We have total manufacturing facilities of around 2, 000 square meters and more than 100 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

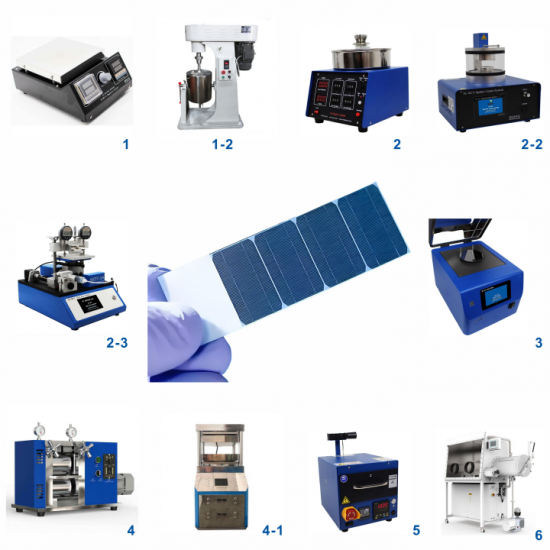

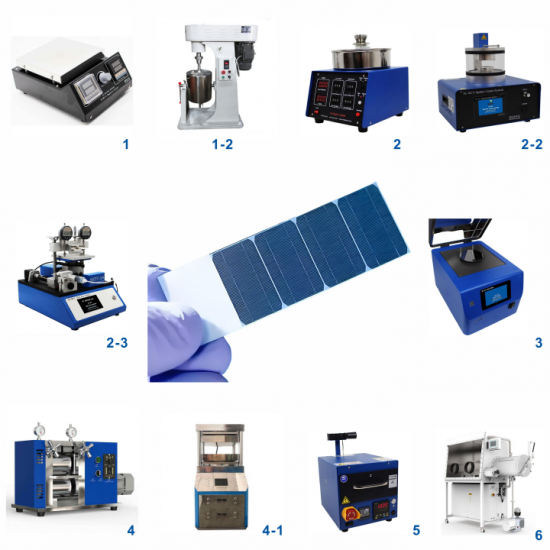

Perovskite solar cells have garnered significant attention due to their potential for high efficiency and low manufacturing costs. Developing and producing these solar cells requires specialized equipment tailored to the unique requirements of perovskite material processing. Below is an overview of the key types of equipment used in the fabrication of perovskite solar cells:

1. Material Deposition Systems

Spin Coating Machines: Commonly used for laboratoryscale production, spin coating is a simple method to deposit uniform thin films of perovskite materials onto substrates.

SlotDie Coating Machines: Suitable for larger scale production, slotdie coating offers a more controlled deposition process, enabling uniform thickness across large areas.

Spray Coating Systems: Useful for applying perovskite layers with good uniformity and can be scaled up for larger area coatings.

Vacuum Deposition Systems: Including thermal evaporation and sputtering systems, which are critical for depositing electrodes and other functional layers such as electron and hole transport layers.

2. Annealing Equipment

Hotplate or Hot Air Gun: Used for annealing processes where the deposited perovskite layer is heated to improve crystallinity and device performance.

Rapid Thermal Annealing (RTA) Systems: Provide precise temperature control and rapid heating/cooling cycles, essential for optimizing the properties of perovskite films.

3. Patterning Tools

Photolithography Systems: For creating patterns on the substrate, necessary for defining the active area of the solar cell and the electrical contacts.

Laser Scribing Machines: Used for patterning and dividing largearea solar cells into smaller modules, ensuring that each cell operates independently.

Cell Fabrication Research

4. Encapsulation Systems

Encapsulation Machines: Protect perovskite solar cells from environmental factors like moisture and oxygen, which can degrade the materials. Effective encapsulation is crucial for enhancing the stability and longevity of the devices.

5. Testing and Characterization Instruments

Solar Simulator: Used to measure the power conversion efficiency of perovskite solar cells under simulated sunlight conditions.

External Quantum Efficiency (EQE) Measurement Systems: Help in understanding how effectively the solar cell converts photons of different wavelengths into electrons.

Impedance Spectroscopy Systems: Useful for studying the electrical characteristics of the solar cells, including charge carrier dynamics and interface properties.

6. Cleanroom Facilities

Given the sensitivity of perovskite materials to impurities and environmental conditions, most fabrication steps are performed in cleanroom environments equipped with air filtration systems to maintain low levels of particulates, maintaining the quality and repeatability of the fabrication process.

Investment in these types of equipment depends heavily on whether the focus is on research and development or moving towards commercial production. Research facilities might prioritize flexibility and the ability to explore new materials and architectures, while production lines would emphasize scalability, reliability, and costeffectiveness. The ongoing advancements in perovskite solar cell technology continue to drive innovations in associated manufacturing equipment, aiming to overcome challenges related to stability, efficiency, and manufacturability.