Perovskite Solar Cell Machine: Innovations in Solar Technology

A perovskite solar cell machine is specialized equipment designed for the fabrication and processing of perovskite solar cells, a cutting-edge technology in the renewable energy sector. Perovskite solar cells are known for their high efficiency, low production costs, and potential for flexible applications, making them a promising alternative to traditional silicon-based solar cells.

● Key Components of a Perovskite Solar Cell Fabrication Research

1. Material Preparation Station

- Chemical Mixing: The machine includes systems for accurately mixing precursor materials needed to create the perovskite layer, often involving materials like methylammonium iodide and lead halides.

- Substrate Cleaning: Substrates (e.g., glass, plastic) are cleaned and prepared to ensure optimal adhesion and performance of the perovskite layer.

2. Coating and Deposition Equipment

- Spin Coater: Used for applying the perovskite solution onto the substrate through spin-coating techniques, allowing for uniform layer thickness.

- Slot Die Coater: This alternative method enables larger-scale production by applying the perovskite layer continuously over wider substrates.

- Sublimation Systems: Some machines may include sublimation techniques to create high-quality thin films directly on the substrate.

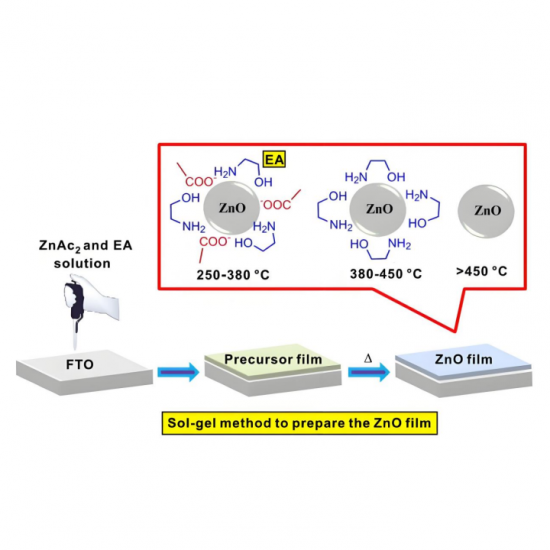

3. Annealing and Drying Units

- Heating Plates or Furnaces: These components are used to anneal the coated substrates, which helps in crystallizing the perovskite layer and enhancing its properties.

- Drying Chambers: These provide controlled environments to evaporate solvents, ensuring that the perovskite layer is properly cured.

4. Layering and Encapsulation Modules

- Electron and Hole Transport Layer Application: Machines often include stations for applying additional layers, such as electron transport and hole transport layers, which are crucial for cell efficiency.

- Encapsulation Systems: These ensure that the final solar cell is protected from moisture and environmental factors, enhancing durability.

5. Testing and Quality Control

- Performance Testing: Integrated systems measure key parameters like efficiency, voltage, and current, ensuring that each cell meets quality standards.

- Inspection Equipment: Automated visual inspection systems may be included to identify defects in the layers or coatings.

● Advantages of Perovskite Solar Cell Machines

1. High Efficiency: The ability to produce high-quality perovskite layers translates to improved solar cell efficiency compared to some traditional methods.

2. Cost-Effectiveness: The lower material costs and simpler processing methods can reduce overall production expenses, making solar energy more accessible.

3. Scalability: Many perovskite solar cell machines are designed for scalability, allowing manufacturers to increase production as demand grows.

4. Flexibility in Applications: The ability to create lightweight and flexible solar cells opens up new possibilities for integration into various surfaces, including buildings and vehicles.

● Considerations for Using Perovskite Solar Cell Machines

1. Material Handling: Perovskite materials can be sensitive to moisture and light; therefore, the production environment must be controlled to prevent degradation.

2. Safety Precautions: Some precursors can be toxic (e.g., lead compounds), so proper safety measures must be implemented during the manufacturing process.

3. Research and Development: Continuous advancements in materials and techniques require ongoing research and development efforts to optimize processes and improve efficiency.

● Conclusion

A perovskite solar cell machine represents a significant advancement in solar technology, facilitating the production of high-efficiency, cost-effective solar cells. As the demand for renewable energy solutions grows, these machines will play a crucial role in the development and commercialization of perovskite solar technology, contributing to a more sustainable energy future.